The New Era of Global Supply Chain Ecosystems- Complex But Strategic

By Mark Millar

Supply Chains are the arteries of today’s globalised economy – they enable the international trade flows that empower global commerce. Today’s Supply Chains are evolving to reflect the increased complexity of world trade – a highly competitive, super connected, fast changing and increasingly volatile global environment, which is progressively more difficult to predict. Supply Chain Management has now become an essential topic across all spheres of management and a strategic agenda item in every boardroom.

Twenty-first-century supply chains have evolved into world-wide inter-connected supply-and-demand networks with profound interdependencies – comprising vastly more complex operations and with greater exposure to the vulnerabilities of our uncertain world. This is leading to greater use of collaborative partnerships, frequently involving outsourcing and off-shoring, creating elongated networks of organisations comprising multiple stakeholders, which require more sophisticated management, control and communication than ever before. Consequently modern supply chains have become complex, multi-layered and inter-connected distribution systems that enable companies and countries to trade more effectively and efficiently.

Developed by innovative, competitive and ambitious practitioners and business managers, these ecosystems have become the essential enablers of international cargo flows around the world, bringing economic and social benefits, and leading to a steady improvement in the standard of living for millions.

Confirming how these networks enable business in an increasingly connected world, the Financial Times’ (FT) lexicon describes how “businesses operate in a broader network of related businesses offering particular products or services – this is known as a business ecosystem”. They further define this business ecosystem as “a network of interlinked companies, such as suppliers and distributors, who interact with each other, primarily complementing or supplying key components of the value propositions within their products or services”.

From the supply chain perspective, Cranfield’s Dr Martin Christopher adopts an end-to-end perspective of the flows of product and accompanying information from the source of raw materials to delivery to the end customer – and sometimes beyond – to develop a definition of supply chain as: “the network of organizations that are involved, through upstream and downstream linkages, in the different processes and activities that produce value in the form of products and services in the hands of the ultimate consumer”.

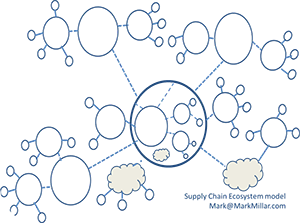

This notion of networks is particularly important, with Christopher reinforcing the key message that modern supply chains are no longer simply linear chains or processes, “they are complex networks – the products and information flows travel within and between nodes in a variety of networks that link organisations, industries and economies”.

Supporting the concept that your supply chain drives competitive advantage for your business, the FT lexicon explains how “Ecosystems also create strong barriers to entry for new competition, as potential entrants not only have to duplicate or better the core product, but they also have to compete against the entire system of independent complementors and suppliers that form the network”.

The linear concept of a chain is therefore no longer adequate to describe today’s complex international networks of suppliers, partners, regulators and customers – together collaborating to ensure the efficient, effective and competitive movement of products, services, information and funds around the world.

These extended multi stakeholder networks have continued to evolve as supply chains have become increasingly strategic, complex and global – we are firmly in the era of Global Supply Chain Ecosystems.

Supply Chain has become Strategic

Leading companies are increasingly considering their supply chains to be strategic – as a business enabler, as a revenue driver and as a differentiator. In several sectors, companies compete on the basis of their supply chains, as much as on their actual products.

For many businesses – particularly those in high tech and consumer electronics – time to market and effective distribution channels are critical success factors, and therefore supply chain management capabilities become a source of competitive advantage.

The supply chain embraces every single activity that enables getting products to customers and consequently touches the vast majority of functions within and across a company. World class organisations no longer perceive the supply chain as merely tactical support for business as usual, but take a holistic position that their supply chain is what drives the business. The latest thinking is that the supply chain is the business.

Supply Chain in the Boardroom

A growing trend in recent years is the presence of supply chain managers serving on the board of directors with the role and title of Chief Supply Chain Officer (CSCO). Standing agenda items for senior executives now include supply chain strategy, supply chain execution and supply chain risk.

Research led by Professor Alan Waller OBE of Solving Efeso, in collaboration with Cranfield School of Management, found that – in stark contrast to just ten years ago – amongst well over half of the companies surveyed, the most senior supply chain person now sits on the Board of the business unit. The research report surmised that this trend is accelerating and concluded that ‘the supply chain is an intrinsic element of the enterprise; its ability to adapt quickly to changes in the commercial environment is critical to the financial and market performance of the business’.

A high profile example of supply chain in the boardroom is Apple. Prior to becoming chief executive, Tim Cook was an acknowledged expert in the often low profile but absolutely critical world of supply chain management. His level of operational expertise and experience is essential for Apple’s continued leadership across global markets with global products amongst global competition, where the supply chain drives competitive advantage through time to market, finely tuned global operations, economically efficient logistics networks and simultaneous worldwide product releases.

Having an increasing presence at-the-table in the executive suite means that supply chain leaders have to learn to speak the language of the boardroom in order to operate effectively and succeed.

Supply Chain and the Chief Financial Officer

Even with many companies having supply chain representation in the boardroom, in reality there is still some way to go before the whole board considers supply chain to be a substantial driving force for the business, in which case there is a real risk of sub-optimising from a strategic planning perspective.

In terms of meaningful engagement with the Chief Financial Officer (CFO), in reality the supply chain has significant material impact on multiple aspects of the balance sheet and profit and loss statements. Supply chain managers can therefore readily translate their activities, influence and results into the business language most suitable for the CFO and the rest of the boardroom – where inevitably money talks!

From the profit and loss perspective, the supply chain function will have a material impact as follows on the business’ income statement:

| Profit and Loss | Supply Chain Impact |

|---|---|

| Revenue: | Customer Service |

| Cost of Goods: | Sourcing & Procurement |

| Capacity Utilisation | |

| Operational Efficiencies | |

| Inventory Management | |

| Warehousing and Transport | |

| Admin Expense: | Order Processing |

| Interest Expense: | Inventory Financing |

Likewise, supply chain activities will impact throughout the Balance Sheet. Accounts receivable and cash assets will be impacted by order fill rates, invoice accuracy and order lead times; whilst balance sheet inventory will be influenced by supplier relationships, supplier management strategies and inventory policies.

The fixed asset categories of property, plant & equipment will directly reflect a combination of the company’s warehouse network, insourcing-outsourcing strategies and build-buy-lease decisions. Order quantities will affect current liabilities whilst the financing arrangements for inventory, plant and equipment will influence long-term debt and shareholder equity.

We still have to question whether supply chain is taken seriously in the board room, maybe the complexity of today’s supply chain ecosystems in fact makes the board of directors bored?

However, when things go wrong, supply chain definitely becomes front and centre on the senior executives’ radar! Somewhat ironically, when in fact perhaps more director level attention to – and participation in – supply chain strategy, supply chain execution and supply chain risk discussions would help to avoid some of the disruptions that impact supply chain performance.

Furthermore, when CFO’s recognise that their company’s supply chain is responsible for between 63 and 90 per cent of a company’s total spend, depending on type of business (according to research by the Supply Chain Council) surely they will then engage more actively in dialogue with supply chain management.

Supply Chain as Competitive Advantage

In our world that is complex, connected and changing fast, the supply chain is more and more being recognised as a key source of competitive advantage and differentiation. Companies strive to build powerful supply chains that will enable them to get their products to market faster, more efficiently and more economically than their competition. Businesses are now competing on the basis of their supply chain management capabilities almost as much as their product or their brand.

Any chain is only as strong as its weakest link – and it’s the same with a supply chain, except that within a supply chain ecosystem the linkages are not consecutive and not linear; there are numerous multi-dimensional connections with profound inter dependencies.

Nevertheless, the strategy of achieving continuous improvement through consistently and persistently working on strengthening the weakest link(s) still applies, and companies adopting such an approach will leverage their global supply chain ecosystem for competitive advantage in our complex, connected world.

Mark Millar is the author of Global Supply Chain Ecosystems – commissioned and published by Kogan Page of London – in which he presents detailed and practical insights that help companies capitalise on market opportunities, overcome supply chain challenges and make better informed business decisions. Acknowledged as an engaging presenter who delivers a memorable impact, Mark has completed over 350 speaking engagements at corporate events, client functions and industry conferences across 23 countries. A Visiting Lecturer at Hong Kong Polytechnic University, Mark is recognised in the ‘China Supply Chain Top 20’, as one of ‘Asia’s Top 50 Influencers in Supply Chain and Logistics’ and in the 2014 USA listing of ‘Top Pros-to-Know in Supply Chain’. Learn more at www.markmillar.com